Simultaneously, these electronic devices are sensitive to various susceptibility requirements, including electrostatic discharge (ESD, e.g., IEC 61000-4-2), and, in some cases, must resist to applied voltages as high as 15 kV. In this instance, the same shielding materials must also feature a very low impedance/resistance at very low frequencies to ensure a harmless discharge path exists to allow the charge to flow from the I/O connectors to the exterior of the chassis, and then safely away from the devices.

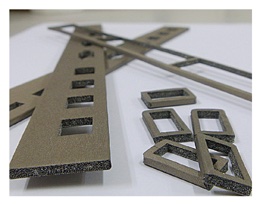

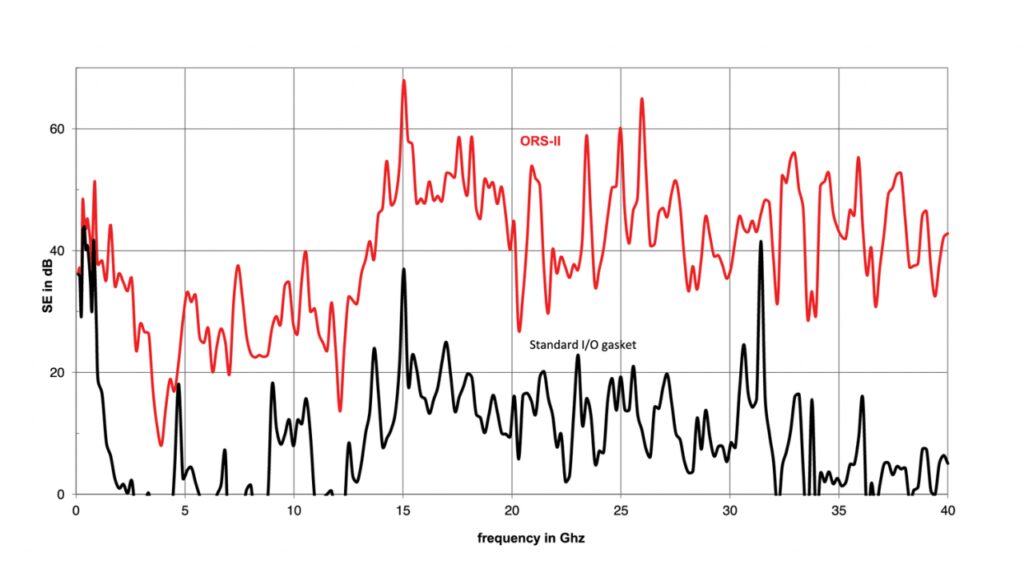

Schlegel Electronic Materials (SEM) introduces ORS-II, a new series of gaskets specially designed for broadband applications. By combining its famous nickel copper plated conductive foam and its high-end nickel copper C12 flexible fabric cladding, ORS-II offers minimal surface resistance to achieve superior grounding and shielding results at low frequencies. By offering excellent Z-conductivity to close the cavities in the chassis openings, ORS-II also ensures substantial shielding performance at high frequencies. ORS-II is available in a variety of thicknesses, which are die-cut to customer specifications, for a durable highly conductive product in all X-Y-Z axes. In addition, shielding efficiency is achieved with less sensitivity to compression variances than other traditional shielding products. ORS-II is available with a UL94-V0 flammability rating and complies with RoHS 2.0 European Directive and SVHC Policy (REACH).

All these features combined in one product makes ORS-II a great engineering solution when addressing all types of shielding challenges which are present in broadband and high-speed applications.

ORS-II is available in a multitude of geometries and in varying thicknesses. ORS-II is recommended for all combinations of I/O connectors, is particularly effective when broadband emissions and/or susceptibility are of concern, and is far more effective than standard conductive foam when superior grounding is important.